Description

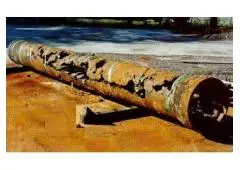

In the realm of metalworking, where precision and efficiency reign supreme, the battle against corrosion is an ongoing challenge. Corrosion, an insidious threat lurking in machining environments, can wreak havoc on equipment, tools, and workpieces, compromising performance and integrity. Amidst this perpetual struggle, corrosion inhibitor additives emerge as stalwart guardians, fortifying cutting oils against the corrosive forces of moisture, oxygen, and contaminants. Their role in preserving the integrity of metalworking operations is indispensable, ensuring longevity, reliability, and quality across various industrial applications.

Understanding Corrosion: The Silent Menace

Corrosion, often described as the degradation of materials through chemical reactions with their environment, is a ubiquitous concern in metalworking. In machining environments where water-soluble cutting oils are employed, the presence of moisture, oxygen, and chemical contaminants creates conducive conditions for corrosion to thrive. Left unchecked, corrosion can lead to surface blemishes, dimensional inaccuracies, mechanical failures, and costly downtime, undermining productivity and profitability.

The Shield: Corrosion Inhibitor Additives

Corrosion inhibitor additives, meticulously engineered compounds, serve as the first line of defense against the corrosive onslaught in cutting oils. These additives function through various mechanisms, including the formation of protective films, chemical passivation of metal surfaces, and interference with corrosive processes. By creating a barrier between metal surfaces and the corrosive environment, corrosion inhibitors effectively mitigate the risk of corrosion, preserving the integrity and functionality of machined components and equipment.

Key Benefits and Applications

Protection Against Corrosion: The primary function of corrosion inhibitor additives is to prevent or minimize the formation of corrosion on metal surfaces exposed to cutting oils. By inhibiting the electrochemical reactions that drive corrosion, these additives extend the service life of machinery, tools, and workpieces, reducing maintenance costs and downtime.

Extended Equipment Lifespan: Corrosion inhibitors not only shield metal surfaces but also protect vital components of machining equipment from corrosion-induced wear and degradation. By maintaining clean, corrosion-free surfaces, these additives contribute to the longevity and reliability of machinery, ensuring uninterrupted operations and optimal performance.

Enhanced Surface Quality: Corrosion inhibitor additives play a crucial role in preserving the surface integrity and aesthetics of machined components. By preventing surface blemishes, staining, and pitting caused by corrosion, these additives contribute to the attainment of high-quality surface finishes, enhancing the visual appeal and functional properties of manufactured products.

Versatility and Compatibility: Corrosion inhibitor additives are designed to be compatible with a wide range of cutting oils and metal alloys, offering versatility in machining applications across diverse industries, including automotive, aerospace, marine, and precision engineering.

Innovations and Future Trends

As industries evolve and environmental considerations become increasingly prominent, researchers and manufacturers are exploring innovative approaches to corrosion inhibition in cutting oils. This includes the development of eco-friendly inhibitor formulations derived from renewable sources, as well as the integration of advanced nanomaterials and surface coatings to enhance protection and performance.

Furthermore, with the rise of digitalization and Industry 4.0 technologies, there is a growing emphasis on real-time corrosion monitoring and predictive maintenance strategies. By leveraging IoT sensors, data analytics, and machine learning algorithms, manufacturers can proactively identify and address corrosion issues, optimizing the efficiency and effectiveness of corrosion inhibitor additives in cutting oils.

Keywords: Lubricity Improver, Rust Inhibitor, Extreme Pressure Additives, Semi Synthetic Cutting Oil Additives, Anti Wear Additives, Metal Working Additives, Cutting Oil Additives, Eco Friendly Cutting Oil, Bounday Layer Lubricants, Additives for Synthetic MWF, Corrosion Inhibitor, Eco Friendly Metal Working Fluid, Just Add & Sell, Lubricity additive, Lubricity enhancer, Lubricity improver for metalworking fluids, Cutting oil lubricity improver, Lubricity Improver for coolant, Lubricity Improver, Lubricity Enhancer, Lubricity Additives, Lubricity Agent, Lubricity Improver for cutting oil, Lubricity Improver for metal working fluid, Lubricity Agent for cutting oil, Lubricity Agent for metal working fluid, Lubricity Agent for soluble oil, Lubricity agent for water based cutting oil, Cutting oil additive rust inhibitor, Rust inhibitor additive for metalworking fluids, Rust inhibitor additive for cutting oils, Rust inhibitor additive for water-soluble cutting oils, Water-soluble cutting oil additive rust inhibitor, Metalworking fluid extreme pressure additive, Cutting oil extreme pressure additive, EP additive for metalworking fluids, EP additive for cutting oils, Extreme pressure additive for metalworking fluids, Extreme pressure additive for cutting oils, Water-soluble cutting oil extreme pressure additive, EP additive for water-soluble cutting oils, Extreme pressure additive for water-soluble cutting oils, Anti-wear additives for metal working fluids, Anti-wear additives for water-based cutting oils, Anti-wear additives for soluble cutting oils, Anti-wear additives for water soluble cutting oils, Anti-wear additive for soluble cutting oil, Anti Wear Additive, Anti Wear Additive for metalworking fluids, Anti Wear Additive for cutting oils, Anti Wear Additive for coolant, Anti Wear Improver, Anti Wear Agent, Anti Wear Improver for cutting oil, Anti Wear Improver for metal working fluid, Anti Wear Agent for cutting oil, Anti Wear Agent for metal working fluid, Anti Wear Enhancer, Anti Wear Agent for soluble oil, Anti Wear agent for water based cutting oil, Metalworking fluid corrosion inhibitor, Cutting oil corrosion inhibitor, Water-soluble cutting oil corrosion inhibitor, Grinding fluid corrosion inhibitor, Corrosion inhibitor additive for metalworking fluids, Corrosion inhibitor additive for cutting oils, Corrosion inhibitor additive for water-soluble cutting oils, Cutting oil packages, Cutting oil emulsifiers, Cutting oil biocides, Cutting oil friction reducer, Cutting oil mist controllers, Cutting oil PH buffers, Component of cutting oil, Ingredients of cutting oil, Chemicals used in cutting oil, Eco-friendly cutting oil, Green cutting oil, Sustainable cutting oil, Environmentally friendly cutting oil, Biodegradable cutting oil, Green metalworking fluid, Sustainable metalworking fluid, Biodegradable metalworking fluid, Metal working additives, Additives for metal working, Metal working fluid additives, Metal working oil additives, Metal cutting oil additives, Metal forming additives, Metal grinding additives, Metal machining additives, Metalworking fluid additive rust inhibitor, Additive for Semi Synthetic Cutting oil, Semi Synthetic Cutting Oil additive, Additive for Synthetic Cutting oil, Synthetic cutting oil additive, Water-based cutting oil additives, Additives for water-based cutting oils, Additives for soluble cutting oil, Water soluble cutting oil additives, Additive for soluble cutting oil, Soluble cutting oil additives, Soluble cutting oil additive, Synthetic cutting oil formula, Formula of synthetic metal working fluid, Formulation of synthetic metal working fluids, What is synthetic metal working fluid, How to make semi synthetic cutting oil, How to make synthetic cutting oil, How to make synthetic metal working fluid, Friction Modifiers, Metal working additives, Formulations of metal working fluid, How to make metal working fluids, Metal Working Fluids Additives, Additives for metal working, Formula of synthetic metal working fluid, Formulation of synthetic metal working fluids, Synthetic cutting oil formulation, What is synthetic metal working fluid, How to make semi synthetic cutting oil, How to make synthetic cutting oil, How to make synthetic metal working fluid, Metal working additives, Formulations of metal working fluid, How to make metal working fluids, Metal Working Fluids Additives, How to make cutting oil, How to make cutting oil, Cutting fluid additives, Cutting oil formulations, Chemicals used in making cutting oil, Cutting oil formula, Formula of cutting oil, Additives required for making cutting oil, Cutting oil additive, Cutting oil formulation, Cutting oil package, Additive for Synthetic Metal Working Fluids, Synthetic metal working fluids Additive, Synthetic cutting oil additives, Additives for synthetic cutting oils, Additives for synthetic coolants,Synthetic MWF additives, Synthetic ester metalworking fluid, Low cost cutting oil, How to make cutting oil, Formulations of cutting oils, Chemicals used in cutting oil, Formulation of soluble cutting oil, Formulations of meta working fluids, Formulations of metal working fluids, How metal working fluids manufacturers, Contains of metal working fluid, Contains of cutting oil, Low cost metal working fluid, Economical cutting oil, Low price cutting oil, How to make cutting oil in home, Chemicals used in making cutting oil, Cutting oil package, Soluble cutting oil package, Eco friendly cutting oil, Green cutting oil, Eco metal working fluid 100, Eco friendly metal working fluid, Ester based metal working fluids, Vegetable oil based cutting oil, Biodegradable cutting oil, Vegetable-based cutting oil, Synthetic ester cutting oil, Biodegradable metalworking fluids, Vegetable-based metalworking fluids, Mineral oil free metal working fluids, Mineral oil free cutting oils, Amine free metal working fluids, Amine free rust inhibitor, Amine free corrosion inhibitor, Chlorinated paraffin free metal working fluids, Amine free cutting oils, Biodegradable metalworking fluids, Vegetable-based metalworking fluids, Synthetic ester metalworking fluids